Industrial Fans

We manufacture and supply specialised and customised fans for all industrial plant requirements. Universal Fans was founded in 1965 and is an internationally recognised company focusing on the design, manufacturing, installation and maintenance of standard and customised pre-engineered fans and related accessories. Fans are manufactured to conform to international legislation, manufacturing and performance standards. Redbacks Engineering has partnered with Universal Fans to bring these products to the Australian market.

Industrial fans are supplied to projects around the globe, including Africa, Australia, the Philippines, China, Canada, Columbia, Peru and Chile.

Fans are manufactured for demanding and high-temperature plant environment. To date, more than 50,000 fans have been supplied to all types of heavy industries.

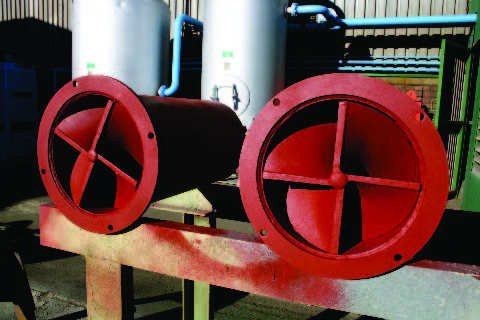

Dynamic Scrubber Dust Collector

Design Features

- High efficiency of up to 99.5% in the 1 to 5-micron range is achieved through “dynamic” action

- Tangential entry of the pre-cleaner section provided dust-drop-out

- “Dynamic” scrubbing involves the use of a wet fan to mix gas, dust and water

- Wet fan is self-cleaning and a prime mover of gas

- Gas capacities of 1,000 to 125,000 Am3/hr

Benefits

- The paddle bladed fan is sprayed with the scrubbing water, thus preventing build-up and wear

- Most of the dust is separated in the inlet section and only final cleaning in the fan and separator

- Prime mover fan is built into the scrubber

- High efficiency with lower pressure-drop due to design

- 35 to 50 tph Steam Boiler applications

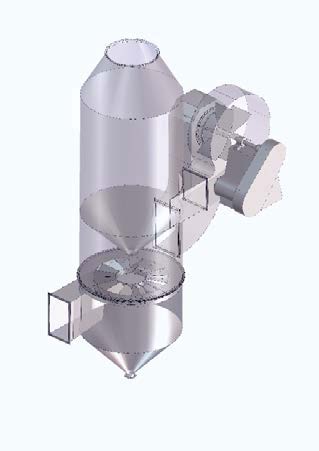

Vane Scrubber Dust Collector

Design Features

- Medium efficiency of up to 95% in the 1 to 5-micron range

- Tangential entry of the pre-cleaner section provided dust drop-out

- No moving parts & low maintenance

- Pressure plate design is critical for the efficiency

- Gas capacities of 1,000 to 100,000 Am3/hr

Benefits

- No moving parts and require minimal maintenance

- Most of the dust is separated in the inlet section and only final cleaning in the scrubber

- Pressure loss over the scrubber could be between 1,5 to 3,75 kPa depending on the application

- Material of construction to suit the application

- Small footprint & can be assembled in the workshop to reduce installation time & cost

- 30 to 35 tph Steam Boiler applications

Venturi Scrubber Dust Collector

Design Features

- High-efficiency Wet Scrubber for particulate removal in the sub-micron range

- Web inlet section wall eliminates build-up and wear

- Modulating throat would maintain a constant throat pressure drop for varying gas loads

- Gas capacities of 1,000 to 550,000 Am3/hr

Benefits

- The collector has minimal moving parts

- Specifically designed to suit all ranges of volumes

- Adjustable pressure-drop over the throat section would give constant efficiency

- Fixed throat or variable throat (Manual or modulating throat design available) design available

- The liquor inlet is via open pipe design and with no use of any spray nozzles that could plug and erode

- Scrubber outlet dust-laden liquor portion can be recycled with clean water make-up

- The inlet section, throat and wet elbow sections are all wet areas and minimal erosion takes place

- Low maintenance due to open pipe liquor inlet and throat designs

- Material of Construction to suit specific client’s needs

Cyclonic Scrubber Dust Collector

Design Features

- High efficiency of up to 98% in the 1 to 5-micron range

- Tangential entry of the pre-cleaner section provided dust drop-out

- No moving parts & low maintenance

- Pressure plate design is critical for the efficiency

- Gas capacities of 1,000 to 500,000 Am3/hr

Benefits

- Flow straighteners close to the gas outlet remove the swirl and improve flow into the ID Fans

- Large scrubbers are manufactured in sections for ease of transport

- Pressure loss over the scrubber could be between 1,5 to 3,0 kPa, depending on the application

- Material of construction to suit the application

- 15 to 200 tph Steam Boiler applications

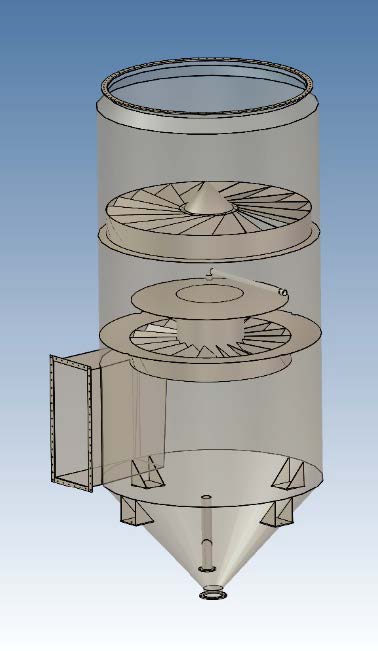

Multicyclone Dust Collector

Design Features

- Low efficiency but with low-pressure drop

- Modular design and can be fitted to custom ducting

- No moving parts & low maintenance

- Gas capacities of 1,000 to 555,000 Am3/hr

Benefits

- The collector has no moving parts

- Minimum space requirements

- Cells can be arranged to fit into existing apertures, due to a modular design

- Good efficiency over a wide range of boiler loads

- Ease of mechanical installation

- Installation before Air Heater / Economiser will protect them from build-up and wear

- Able to manufacture in sections for container shipping if required

- Low resistance to gas flow resulting in low power absorption